We deliver expert metallurgical investigations and lab-backed failure analysis services to uncover the causes behind material or weld issues—offering data-driven solutions to prevent recurrence and improve reliability.

🧪 Failure Analysis & Material Characterization:

Failure Investigations – Weld failures, base metal cracks, corrosion, fatigue, and brittle fracture

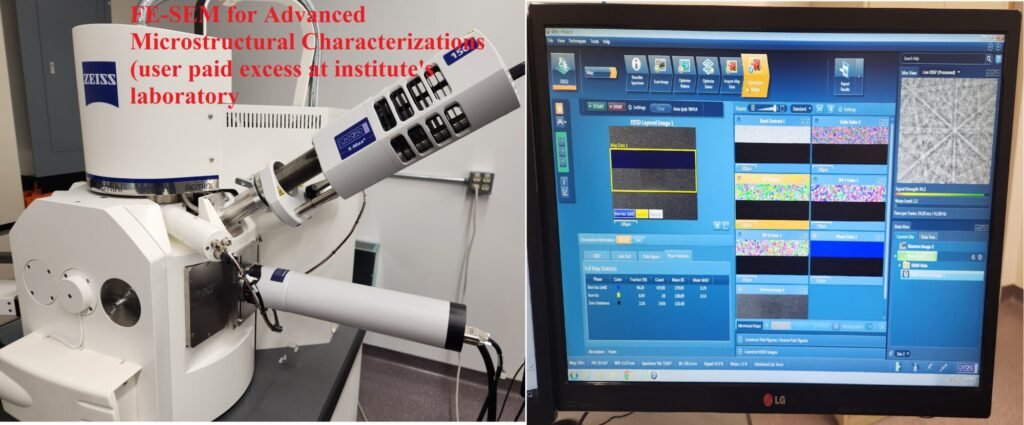

Microstructural Evaluation – Optical microscopy and scanning electron microscopy (SEM)

Hardness & Microhardness Testing – Post-weld HAZ profiling, material property validation

Chemical Composition & PMI Testing – Lab-supported analysis for unknown or suspect materials

Heat Treatment Verification – Metallurgical confirmation of process effectiveness

Root Cause Analysis (RCA) Reports – Clear, documented, and evidence-based conclusions

🔗 Global Lab Collaboration & Technical Research:

Partnered with Accredited Labs – ISO/IEC 17025 certified partners across Canada, India, and the U.S.

Advanced Testing Capabilities – SEM, EDS, XRD, Charpy impact, creep testing, and more

Welding Metallurgy Research Support – Support for procedure development, WPS optimization, and base material behavior

Consultation for Litigation or Insurance Claims – Clear, expert-backed documentation and witness support when needed

👷 Delivered by Qualified Experts:

rofessional Engineers (P.Eng.) with Metallurgy Focus

Welding Engineers with Research & Industry Experience

Lab-Experienced QA/QC Experts – Bridging field and lab results for practical understanding

Support for Industry Codes – ASME, AWS, ASTM, API, ISO, and CSA

Slogan: “Delivering Clarity Through Science – By the Book, With Trust.”

© Copyright 2018 TrueQMS Inc.